一、主要技术规格Main Tech Parameters

|

原材料(钢带)材质 Steel strip material |

热轧或冷轧低碳钢Hot rolling or cold rolling low carbon steel |

|

成品要求 FinishedProducts requirements |

圆管round pipeФ50-Ф102mm,thickness 壁厚:1.0-4.0mm 方管square pipe 40X40-80X80mm, thickness壁厚:1.0-3.5mm |

|

机列要求Machine column requirements |

机列形式:分体式 Form:Split |

|

布置方式:根据客户的需求 arrangement form: according to the customer's requirements |

|

|

机组生产速度 Unit production speed |

0~70m/min(特定条件下无法达到最高速度 The maximum speed can not be reached under certain conditions |

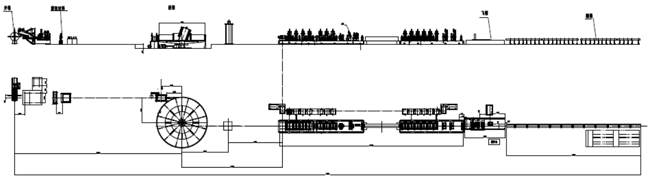

二、工艺流程Working Flow

开卷→剪切对焊→螺旋活套→校平→轧制成型→高频焊接→刮刀→冷却 →定径→矫直→飞锯切料→下料台

hanging material→feeding→uncoiler→shear and butt welder→horizontal spiral accumulator→forming→high frequency welding→scraper→cooling→sizing→straightener→computer control flying saw→lay out table

三、焊管线主要构成规格MainlyComposed Specifications Of Pipe Line

1、开卷机 Uncoiler

|

结构形式 type |

单头液压开卷机single headhydraulic uncoiler |

|

适用钢带内径 Shrinking and expanding range of I.D |

钢卷内径涨缩范围φ470-φ520mm(根据客户需求) Φ470-Φ520(according to the customer’s request) |

|

钢带外径 steel strip O.D |

≤φ1800mm |

|

钢带宽度 Steel strip width |

160~320mm |

|

钢带卷重 Steel strip coil weight |

≤5吨Ton |

|

制动形式 Brake from |

气动、强弱制动Pneumatic brake |

|

转动形式 rotation form |

人工推动平台±180°Manual push platform±180° |

2、液压剪切手工对焊机或自动焊Hydraulic Shear And Manual Butt Welder Or Automatic Type

|

作用Function |

切除钢带头尾的缺陷部分以及带卷中间的缺陷部分 在对焊前切头切尾,使对焊接头平直对正,利于对焊 Removal of the defective portion of the strip head and tail and coil center, Cutting head and tail before butt welding, make the butt-welded head straight on to be good for welding |

|

结构形式 Structure form |

液压剪+手动(自动)焊接+手动(自动)对缝 Hydraulic shearing and manual(Automatic) alignment and manual(Automatic) welding |

|

剪切厚度 Applicable steel strip thickness |

≦4.0mm |

|

最大剪切宽度 Maximum steel strip width |

320mm |

3、盘式螺旋活套HorizontalSpiralAccumulator

|

活套原理 Principle |

由外套引入,中心出料 Introduced by theouter accumulator, center discharge |

|

活套直径 Diameter |

Ф4.8米meter |

|

钢带宽度 Steel strip width |

160~320mm |

|

钢带厚度 Steel strip thickness |

≦4.0mm |

|

充料速度 Feeding speed |

≥120m/min |

|

送料电机功率 Feeding motor power |

11KW |

|

活套主体功率 Accumulator unit motor power |

22KW |

4、成型定径机组Forming And Sizing Machine

|

进料装置 Feeding device |

导向立辊 Guide vertical roll |

矫平辊后两对导向立辊,通过手动调节对中开合调整 After leveling roll two pairs of vertical guide rollers, regulation of the opening and closing by manual adjustment |

|||||

|

矫平辊 Leveling roller |

采用7辊矫平装置,使钢带平稳进入成型机组,矫平辊为无动力辊,下辊固定,上辊通过首轮丝杆上下调整 Adopt7-roller leveling device, so that a smooth strip into the forming units, leveling roll is a non-powered roller, lower rolleris fixed, upper roller can be adjustedthrough the first round screw up and down |

||||||

|

成型机架 Forming bracket |

成型原理 principle |

本机组采用底线水平辊式成型原理,轧辊采用双半径孔型 This unit uses the baseline level roll-forming principle,Roller adopts double radius of groove |

|||||

|

成型要求 forming requirements |

圆管round pipeФ50-Ф102mm,thickness 壁厚:1.0-4.0mm 方管square pipe 40X40-80X80mm, thickness壁厚:1.0-3.5mm |

||||||

|

成型机架规格 Forming bracket specifications |

辊架 Roller bracket |

数量 quantity |

辊架轴径 Shaft diameter of roller bracket |

辊轴材料 Material of roller bracket |

轴热处理 Heat treatment |

||

|

水平辊架 Horizontal Roller bracket |

7 |

Φ90mm |

42Crmo |

调质高频淬火 HF quenching |

|||

|

立辊架 Vertical Roller bracket |

7 |

Φ60mm |

42Crmo |

调质高频淬火 HF quenching |

|||

|

成型机架机构要求 Forming bracketinstitutions requirements |

在每个开口成型水平机架上辊方轴承顶部都设由过载保护装置,当遇到过载时该垫有缓冲,以保护水平辊和传动装置 On each opening forming horizontal rack roller bearings are located at the top side by the overload protection device, the pad has a buffer when faced with overload, in order to protect the horizontal roller and transmission device |

||||||

|

水平辊架为龙门式结构,其中:开口成型4机架;闭口成型3机架。水平辊模具采用隔套直接固定,保证机组精度 Horizontal rollerbracket is gantry structure, including: open molding4 brackets; Silent molding 3brackets. Horizontal rollermold adopt spacer fixed directly, ensure its accuracy |

|||||||

|

立辊架为滑槽式结构,其中:双立辊导向,手动调节同时开合和对中;立辊滑块为分体式,用螺钉调节松紧; Vertical roller is sliding-type structure, including: double vertical roller Guide,manually adjust the opening and closing at the same time vertical roll slideris the split, with screw to adjust tightness |

|||||||

|

换辊方式:侧拉式 Roller changing way:Side pull |

|||||||

|

机架润滑:水平辊架后端排架使用油枪油脂润滑,配加油嘴 BracketLubrication:horizontal rollerbracket back-end bent use grease lubrication oil gun, with refueling nozzle |

|||||||

|

|

上下轴加同步调整手轮 Upper and lower axis synchronous adjusting handwheel |

||||||

5、焊接设备(机械部分) Welding Unit

|

焊缝导向机架 Weld guide bracket |

(1套)导向辊由上下两个辊子组成,中间装有导向刀片,焊缝角度通过螺杆调节 (1 set)Guide roller is composed of upper and lower rollers, the middle is equipped with guide blade,weld angle adjusted through the screw |

|

焊接挤压辊机架 Welding extrusion rollerbracket |

(1套)三辊式,压辊加压将熔融的金属挤压并焊合在一起 (1 set)Three roller, roller pressure squeezing molten metal and welded together |

|

侧挤压辊轴装辊直径 Roller diameter ofThe lateral extrusion roller |

Φ60mm |

|

外毛刺去除装置 Outer burr removal device |

(1架)装有可交替使用的前后刀具座,手轮调整刀具的高度和横向位置并加装有快速进退刀装置 (1 set)Before and after the tool holder can be used interchangeably, the handwheel adjustthe cutting tool height and horizontal position and equipped with a fast cutting device |

|

下支承部分 lower support part |

硬木板支承,高度可调;可保证焊缝切削光滑平整 Hard wood supports, height is adjustable; can ensure the seam cutting is smooth |

|

磨光辊机架 Polishing roller bracket |

(1架)立辊式,手动调节开合和对中 (1 set)Vertical roller, manually adjust the opening and closing |

|

冷却装置型式 Form of cooling device |

喷淋和溢池联合式 Spray pool and overflow pool |

6、定径机架Sizing Bracket

|

定径要求 Sizing requirement |

圆管round pipeФ50-Ф102mm,thickness 壁厚:1.0-4.0mm 方管square pipe 40X40-80X80mm, thickness壁厚:1.0-3.5mm |

|||||

|

定径机架规格 Sizing bracket specifications |

辊架 Roller bracket |

数量 quantity |

辊架轴径 Shaft diameter of roller bracket |

辊轴材料 Material of roller bracket |

轴热处理 Heat treatment |

|

|

水平辊架 Horizontal Roller bracket |

6 |

Φ90mm |

42Crmo |

调质高频淬火 HF quenching |

||

|

立辊架 Vertical Roller bracket |

6 |

Φ60mm |

42Crmo |

调质高频淬火 HF quenching |

||

|

水平辊模具采用隔套直接固定,保证机组精度 Horizontal rollermold adopt spacer fixed directly, ensure its accuracy |

||||||

|

定径机架机构要求 Sizing bracketinstitutions requirements |

换辊方式:侧拉式 Roller changing way:Side pull |

|||||

|

上辊调整:左右单独调整 Adjustment ofUpper roller: left or right to adjust alone |

||||||

|

立辊架为滑槽式结构,双立辊导向,手动调节同时开合和对中;双立辊导向,手动调节同时开合和对中;立辊滑块为分体式,用螺钉调节松紧 Vertical roller is sliding-type structure, including: double vertical roller Guide,manually adjust the opening and closing at the same time,vertical roll slideris the split, with screw to adjust tightness |

||||||

|

矫直装置(土耳其头) Straightener(Turkey head) |

作用 Function |

矫直钢管平直度,引导钢管正确进入飞锯,也可对方矩管进行整径 Straightening steel pipe straightness, lead the steel pipe right into flying saw, can also be rectangular tubes for the whole size |

||||

|

结构 structure |

四辊土耳其头,分别上下、左右调整和旋转调整 Four-roll Turkey head, up and down, left and right adjustment and rotation adjustment respectively |

|||||

|

数量 quantity |

两架单面土耳其头 Two Single-sided Turkey head |

|||||

|

型式Type |

微机定尺飞锯 computer length flying saw |

|

用途 Usage |

确定钢管定长切断位置,并能快速起动使切断设备与作业线速度同步 Determine steel pipe fixed length cutting position, and can quickly start to make the cutting device synchronized with the production line |

|

维持切断设备与作业线速度同步,切断机构动作切断钢管 Maintaining cutting device synchronized with the production line, cutting off steel body movements and steel pipe |

|

|

快速复位 Fast reset |

|

|

控制方法 Control way |

微机控制电机通过减速箱传动齿轮齿条驱动移动组件 Microcomputer control motordrives mobile component through gear boxgear rack |

|

切割方式 Cutting way |

热摩擦锯切 Friction heat of mental sawing |

|

锯车最大运行速度 Maximum running speed of saw car |

70m/min |

|

锯切管径 Pipe diameter |

圆管roundФ50-Ф102mm,方管square 40X40-80X80mm |

|

锯切管壁厚 Pipe thickness |

≤4.0mm |

|

切割精度 Cutting precision |

±3mm |

|

定尺长度 Specified length |

4~10m |

|

锯片规格 Saw blade |

Φ800×110×4 |

|

锯片转速 Saw blade rotation speed |

3000rpm |

|

锯切电机 Cutting motor |

15KW(AC) |

|

跟踪电机 Tracking motor |

22KW(DC) |

|

气动系统 Pneumatic system |

0.4~0.7Mpa |

8、后辊道架Run Out Table

|

支架结构形式 Support structure |

采用型钢焊接结构 Using steel welded structure |

|

辊道架标高Roller rack elevation |

与管件轧制、飞锯下料中心标高一致 In line withpipe rolling andflying saw cutting center elevation |

|

托辊形式、材料 Idler roller form and material |

托辊为平辊,材料:45#钢淬火镀硬铬,使用寿命长,不划伤钢管 Idler roller is flat roller Material:45# steel quenching hard chrome plated, long service life, don't scratch steel pipe |

|

托辊运转动力 Operation power of idler roller |

采用3KW电机拖动,可满足不同生产速度的需求 Adopt 3kw motor, can meet the needs of different production speed |

|

翻料方向 Turning direction |

管件前进方向 |

|

下料方式Blanking way |

两边都可下料can be blanking on both side |

四、传动系统Transmission system

|

传动原理 Principle |

整个机组成型机和定径机联动传动,各系统的主电机通过减速箱、齿轮箱(螺旋伞齿轮传动)、万向传动轴拖动水平辊;立辊为无动力辊。螺旋伞齿轮材质采用20CrMnTi Forming and sizing machines of the entire unit Transmission linkage, the main motors of each system drag horizontal roller through reducer, gear box (spiral bevel gear), universal transmission shaft; vertical roller is unpowered roller. Spiral bevel gear material used 20CrMnTi |

|

主机机组电机 The host unit motor |

132KW x2 |

|

齿轮箱润滑 Gearbox Lubrication |

稀有浸泡润滑;箱体外有油位显示 Rare immersion lubrication; There is oil level outside the enclosure |

|

额外 additional |

先将油循环冷却系统预先准备,现场需要时再增加。 Oil circulating cooling system in advance to prepare first,will add if need when install. |

五、水管分布Water pipe Distribution

|

结构 Structure |

整机预留冷却液总接入口,每段轧辊中间安装可调金属冷却管喷淋头 Reserve the engine cooling fluid total access, installing adjustable metal cooling spray headin the middle of each roller |

|

冷却液流量 Coolant flow rate |

≥25吨ton/小时hour |

|

主电机 Main motor |

国产品牌 Domestic brands |

|

减速机 Reducer |

国产名牌Domestic brands |

|

飞锯电源 Flyingsawpower |

进口品牌Imported brands |

|

汽缸、气动元件 Cylinder, pneumatic components |

国产品牌Domestic brands |

|

成型、定径机组轴承 Bearingof forming and sizing bearing unit |

国产品牌(哈、洛、瓦)Domestic brands |

|

主要电器元件 Main electric components |

进口品牌Imported brands |

|

固态高频 Solid state high frequency |

400KW节能一体机固态高频,单拖,风水冷,空调,调整支架 400KW energy-saving all-in-one machine solid state high frequency, single drag, airand water cooling, air conditioning, adjustment bracket |

江阴市银江机械有主导产品有:开卷机、剪切机、螺旋活套、焊管成形设备等,是一家集研发,设计,生产,销售为一体的专业制造厂家。

江阴市银江机械有主导产品有:开卷机、剪切机、螺旋活套、焊管成形设备等,是一家集研发,设计,生产,销售为一体的专业制造厂家。